Glastonbury gets on-board with Plaswood

Aside from many of the biggest and best names in global music, Glastonbury now features a unique example of just how effective modern plastic recycling can be.

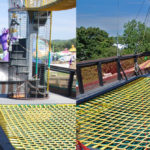

Located in the Green Kids Field, the Cadmus is a giant 40 foot long, 40 foot tall and 20 foot wide play ship constructed not out of wood but from an innovative recycled plastic alternative to wood known as Plaswood.

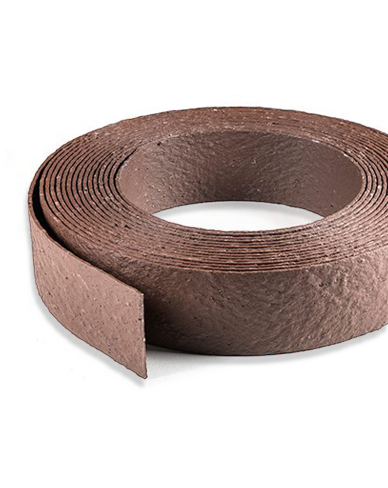

Plaswood is manufactured by British Polythene Industries (BPI) plc - a business which ranks not only as Europe's largest manufacturer of polythene films, bags and sacks, but also as Europe's largest recycler of waste polythene.

Every tonne of polythene BPI recycles not only diverts waste from landfill but conserves the Earth's dwindling oil reserves. It also cuts carbon and other harmful emissions. Plus, using Plaswood for marine applications such as jetties, pontoons and decking negates the need to use tropical hardwood, preserving the world’s shrinking tropical rainforests.

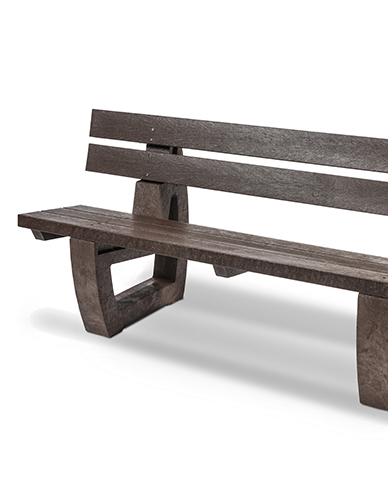

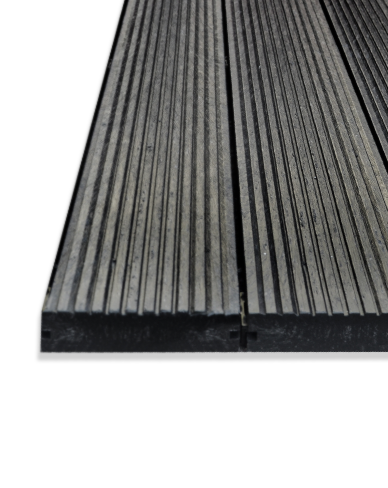

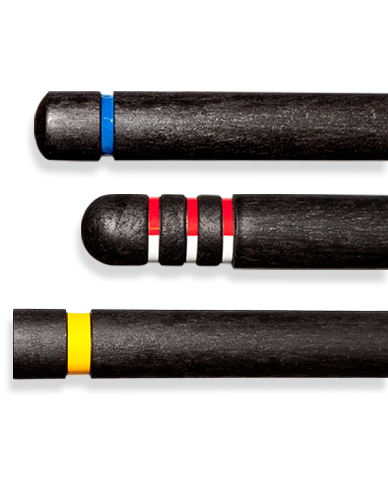

Named after the Phoenician prince credited with introducing the original alphabet, the Cadmus was constructed by Mark Cann and Loz Harris - two Cornish shipwrights more used to building luxury yachts. Plaswood planks were employed for the ship’s hull whilst Plaswood decking was utilised for its inner and outer play decks and for its steps.

The decision to use Plaswood was taken by the founder of Glastonbury, Michael Eavis himself. Michael had previously seen Plaswood in use at other children’s play areas and had been impressed by its strong green credentials.

In addition, as a significant amount of plastic waste had been collected for recycling at last year's Glastonbury festival, he was keen to use a material that may well be eploying some of that reprocessed material.

Commenting on the completed project, Mark Cann, shipwright, said: “Building the Cadmus has been hard work but it’s most definitely been a labour of love. We’ve worked with Plaswood before to create floating pontoons and other play areas and aside from its strong environmental credentials, it offers a number of other benefits.

“Most notably, it doesn’t crack or fade, it doesn’t splinter, it’s totally inert and unlike wood, there’s no dust created from working with it. The finished ship looks fantastic and all of the team, Michael Eavis included, is absolutely delighted with it.”

Mike Baxter, a director at BPI, added: “BPI is at the vanguard in making polythene a more sustainable choice. Not only are we Europe’s largest polythene recycling but we are a leader in developing 100% recyclable products that are also downgauged – meaning more performance is offered from less material.

“Our stakeholders, our customers and many in our industry are already familiar with this strong environmental focus but we’re delighted to be supporting the Cadmus as it allows us to demonstrate our greener approach to a new and particular eco-aware audience.”