Fit and Forget

The Plaswood Group has been listed as our highly deserved Recycled Plastic Specialist of the Month, we are pleased to announce here at Building and Facilities News.

Plaswood’s roots date back to 1983, when the material was first manufactured by Gloucestershire-based PCL, a business in the recycling waste plastic industry that needed to attain additional outlets and products for the mass of plastic pellets it produced. It was only a year later when the company was acquired by British Polythene Industries (BPI) and the ongoing success that ensued made re-locating to its dedicated Recycled Products factory in Dumfries a necessity.

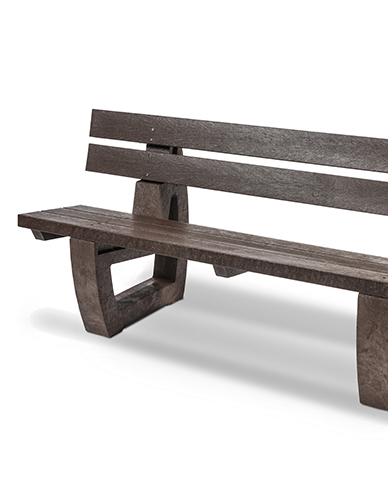

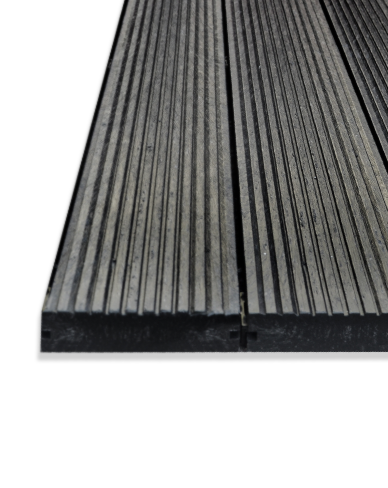

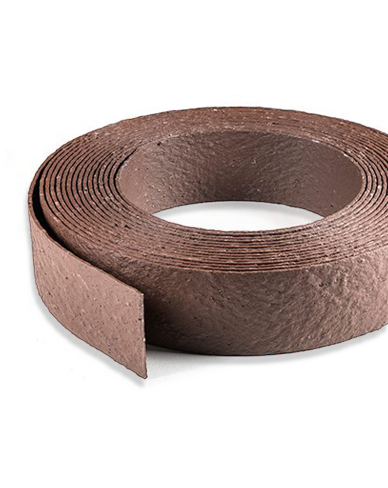

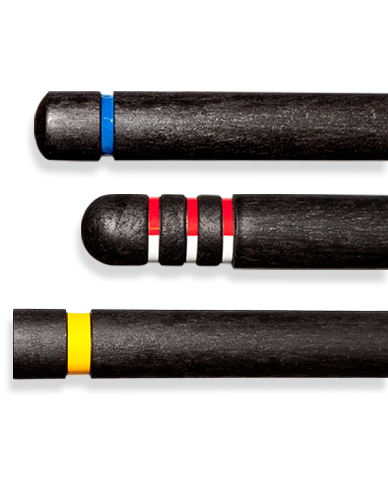

Plaswood’s parent company, BPI Recycled Products is now the UK’s largest recycler of waste plastic films, boasting an annual recycling capacity in excess of 100,000 tonnes and an ability to recover components from a variety of manufacturing and business verticals (namely the agricultural, courtesy of the waste farm plastics collected). As reputable recyclers of waste plastic and manufacturers and suppliers of Plaswood lumber, street furniture and construction materials, the company is well placed to provide solutions for schools & playgrounds, parks & gardens, wetlands & waterways, streets & car parks, town & city centre and structural & architectural applications.

“We serve a broad range of businesses across the construction spectrum with our perfect wood substitute,” Mike Baxter, BPI Recycled Products Director responsible for the Plaswood Group, informed us. “Because it doesn’t wear, rust or degrade with age, it adds real value over the life of the product, especially in wet or outdoor environments where wood need to be painted annually. It has a clear edge over wooden structures particularly in relation to marine applications simply because it will not rot.”

Although robust, Plaswood is flexible in the sense it can be formed into many shapes, being easily adapted using standard tools in conjunction with other materials. Due to its construction from technically superior waste agricultural plastics the high performance product is non-absorbing and weatherproof, which makes it a whole lot more sustainable and cost-effective than its more traditional counterparts (concrete, steel and wood). In addition, the eco-friendly material doesn’t require painting or preservation once fitted, and after usage it can be fully recycled for further environmental consideration.

“As a leading manufacturer and supplier of recycled plastic products we recognise our responsibility to operate with due concern for the environment in which we live and work and to minimise the impact of our activities on that environment,” Mike concluded. “Through close contact with national governments and industry regulators we are at the forefront of legislative developments. We continue to develop our processes and working practices to meet, as a minimum standard, both our legal and social obligations.

“We continually seek to improve our performance by setting objectives and targets combined with clear management programmes and initiatives to minimise our impact on the environment. The market for more sustainable construction and building materials continues to grow; we will invest and enlarge our production facilities to meet this increased demand for our products.”

Excitingly, Plaswood’s parent company British Polythene Industries experienced further expansion as it was recently acquired by the RPC Group. This has in turn made the businesses (once combined) one of the world’s largest plastics suppliers and recyclers. If you would like to find out more about the company and its range of recycled plastic lumber then please contact Plaswood today.

Download the Recycled Plastic Specialist of the Month Datasheet