The Challenge

The Cotswold Canal forms a thirty-six mile long waterway comprised of two connected Gloucestershire waterways, The Stroudwater Navigation and the Thames & Severn Canal, which link two of England’s great rivers: the River Severn and the River Thames.

For several years The Cotswold Canal Trust has been painstakingly restoring parts of the Cotswold Canal, which originally date back to the eighteenth century. Their aim was to restore the Cotswold Canal as a navigable route from the Stroudwater Navigation’s junction with the Gloucester-Sharpness Canal at Saul Junction to the River Thames at Lechlade.

Major infrastructure developments required included a new road layout, new locks, bridges and excavation of the original canal channel. The work also involved maintaining the long distance footpath, the Thames & Severn Way, which follows as closely as possible the towpath of the Stroudwater Navigation and Thames & Severn Canal.

The canal, which is over two hundred years old, was at risk from the fast flowing River Frome, which was encroaching on the narrow causeway that separates the river from the canal channel. Left untouched this erosion would ultimately have caused the towpath to collapse and disappear.

The Solution

A restoration project was required for the preservation of the area’s local heritage and to protect against the destructive effects of the fast-paced river.

The trust needed to restore a five hundred metre stretch of the Ryeford Causeway Canal bank and towpath and the historic Ryeford Wharf, near Stroud, Gloucestershire.

The Cotswold Canal Trust chose to work in partnership with Help for Heroes and their career recovery programme called Heritage Heroes. The two year programme sees Heritage Heroes working alongside skilled volunteers from the Canal & River Trust, giving the Heritage Heroes the opportunity to learn heritage skills and gain new qualifications, in order to help them find new career paths.

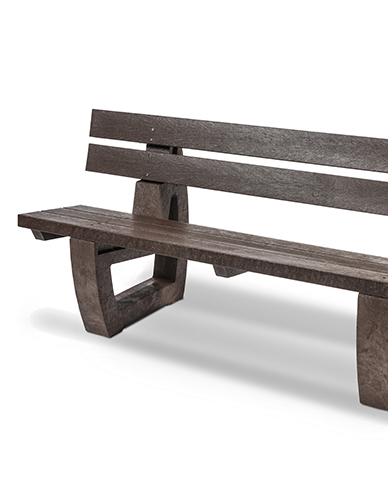

Plaswood ‘plastic’ lumber posts were selected as the ideal material to help rebuild the new canal bank. Plaswood high performance lumber, manufactured by BPI Recycled Products and made from 100% recycled plastic, offered a sustainable and cost-effective alternative to using traditional materials such as hardwood, concrete and steel.

Plaswood has been used by the Cotswold Canals Trust on other canal restoration projects, such as new lock bridges at Blunder Lock Gate, as it is highly suitable for applications such as revetment walls and embankment support due to its strength and long life expectancy.

Technique used

Tree stumps were removed from along the bank and the bank edge was excavated using a 1.5 tonne machine to create a flat, angled profile down to a line around 500mm below water line. Surface scrub, underwater debris and masonry obstacles were also removed prior to piling. The removed soil was deposited and reused as appropriate as backfill after inserting posts and liner in the canal.

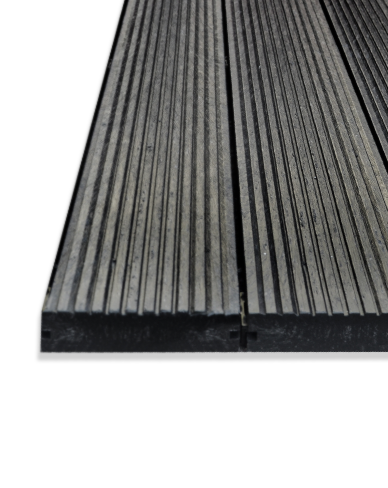

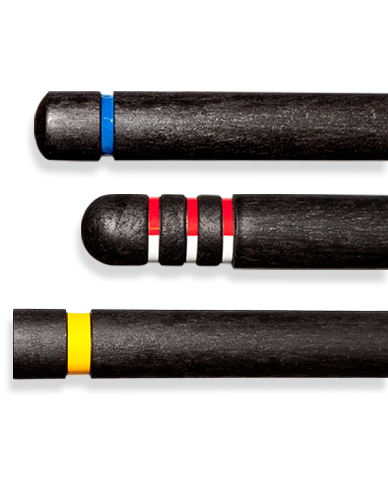

The bank edge was constructed using 50x100mm rectangular section (solid) black recycled Plaswood plastic posts 2.1m and 1.55m long driven into the canal bed with a 500mm spacing. Bottom edges were chamfered using a mitre saw on two sides to ease installation. The top edges sit 500mm above normal water level, to allow for a reasonably shallow slope to the new earth bank.

Plaswood posts were installed safely using a high-frequency hydraulic piling hammer fitted with a piling head suitable for the rectangular shaped posts. A fabricated steel piling frame with 6 x 100mm square hollow sections was used to line up and insert six posts consecutively. Once the six posts were driven 500mm off normal water height the frame was repositioned with its end segment over the last driven post and lined up to drive a further five posts in and so on. The piling hammer was supported laterally by hand, using scaffold planks supported on the barge and the towpath and the piling hammer and excavator operators operated in unison to install the piles.

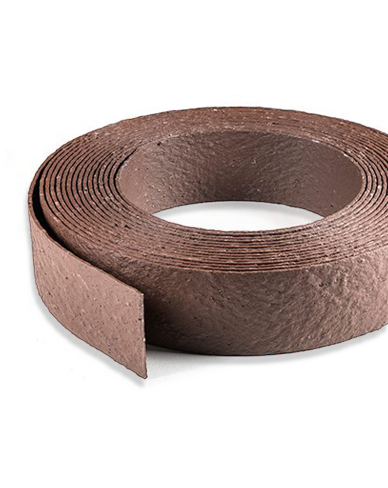

Half the Plaswood posts were cross-cut to 2.1 and 1 metre lengths, with the other half cut to 1.55m long pieces. The king posts were spaced at 1m centres (between canal side posts). After chamfering one end of all three types of posts by 45 degrees to their centre-lines, each post had 4mm deep groove cut across its non-chamfered (upper) end to fix the stainless steel tie to. The steel tie wires were used to ensure the posts and felt liner held the infill soil. After inserting posts, a sturdy felt liner was screwed using 100mm long stainless steel hexagon head coach screws and washers. The felt liner sat on top of the posts and fixed to the tops using cappings made from Plaswood that matched the posts. The liner ran down the inside of each post and into the lowest part of the clean triangle created beforehand by the excavator. The liner was screwed at every other canal post at a low point on the inside of the post, just above water level, then laid up the bank angle to a suitable point below the finished towpath level using all of its 2 metre width.

The posts alone didn’t have the sufficient strength to act as simple cantilever support for the felt liner and soil backfill. Therefore stainless steel wires were used to tie them back to shorter Plaswood king posts just outside the outer edge of the towpath and set at approximately 20 degree angle in the ground, using one king post to every two outer posts with the wires lying just below the finished soil surface.

After approximately 25 metres of post/felt membrane is been installed, the void behind the felt was backfilled with dredged material from the canal edge, using a barge-mounted hydraulic crane and a clamshell bucket, taking care not to undermine the new posts.

The Result

The Chief Executive of the Cotswold Canals Trust, Ken Burgin, said: “Once again we have successfully used Plaswood for canal restorations due its strength, longevity and the low maintenance it requires. He added: “The generous donation from BPI Recycled Products has also meant that the Heritage Heroes volunteers have been given hands on experience of working with modern and innovative building materials that are ideal for wet environments and offer industry leading performance standards for waterways management professionals.” Plaswood is becoming increasingly popular with waterways management professionals, architects, builders’ merchants, civil engineering and construction contractors, and local authority specifiers and buyers.