Timber - A Perfect Circle

How more informed material choices will be an important part of the construction industry’s journey to develop more sustainable building practices.

A significant development in the drive to create a more sustainable world has been the move towards a circular economy as an alternative to the traditional linear version of ‘make, use, dispose.’ Whereas with the linear approach, raw materials are collected, transformed into products and ultimately disposed of, under circular economy principles, the lifecycle of a material is extended as long as possible, with recovery, recycling and regeneration at the end of each service cycle.

That’s according to Katherine LorekWallace, general manager of recycled timber manufacturer Plaswood® . “For the construction industry, the challenges of progressing towards a circular economy are perhaps greater than many other sectors,” she says.

“The Department for Environment, Food and Rural Affairs (DEFRA), for example, has reported that 62% of total waste accumulated in the UK is down to construction, demolition, and excavation; and the Circular Economy impact organisation claims that global construction of housing and infrastructure has the largest resource footprint at 38.9 billion tonnes.”

Lorek-Wallace adds that, nevertheless, the industry is actively seeking ways to improve its environmental profile. “One way that this can be achieved is through making more informed choices in the selection of materials,” she says.

Since a substantial part of the circular economy requires keeping products in use for as long as possible, a proactive way to make this happen is to focus on continued usability when purchasing building material and products.

“In the selection of timber, for example, although responsibly sourced organic timber is considered a long-lasting and renewable resource, it can often be affected by the vagaries of the elements and may require frequent treatment to maintain its effectiveness. And when it comes to disposal, often construction timber is not recycled efficiently on a large scale, mainly due to limited waste management options.”

“In particular, facilities which do offer timber recycling are highly selective in what goods they do accept. Those who are willing to deal with the practical difficulties of transporting their timber waste regularly face rejection due to their timber containing unknown levels of contamination from adhesives, surface finishes and other non-biodegradable elements. Even when such waste is recyclable, the profitability for this effort is low.”

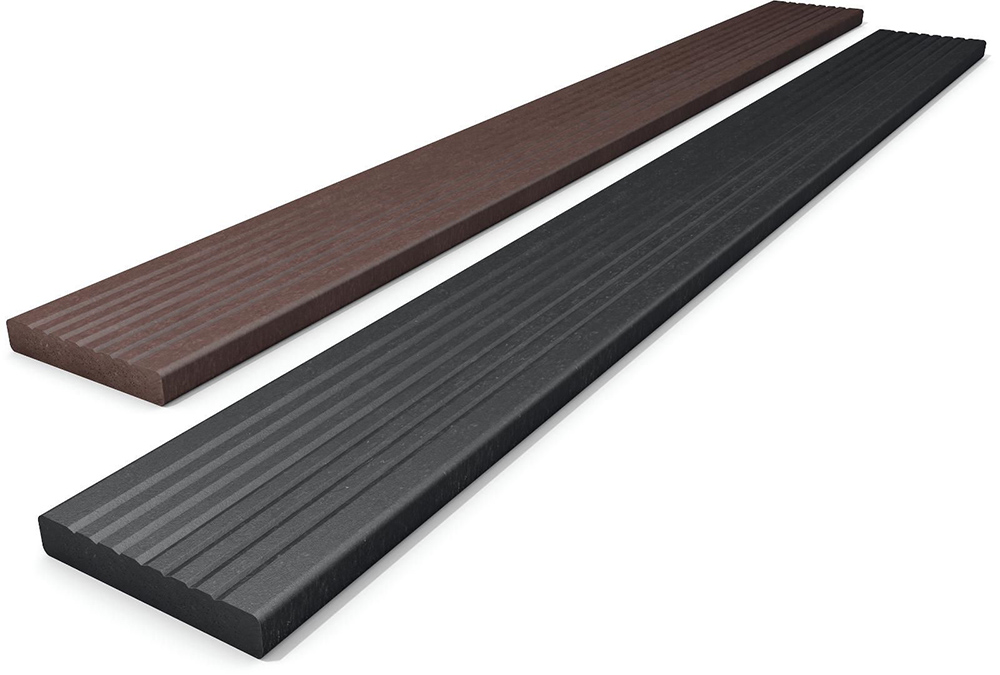

Lorek-Wallace says that, as an alternative, plastic timber already provides an ideal demonstration of the circular economy in action, as it is manufactured from 100% recycled plastic removed from the waste

stream.

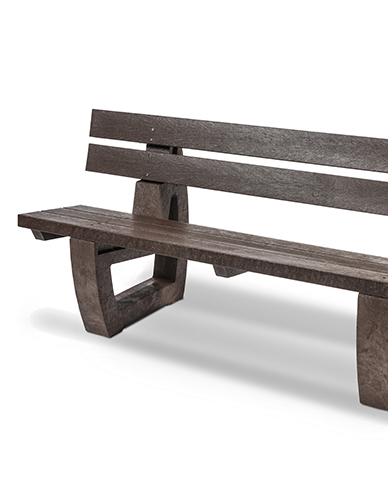

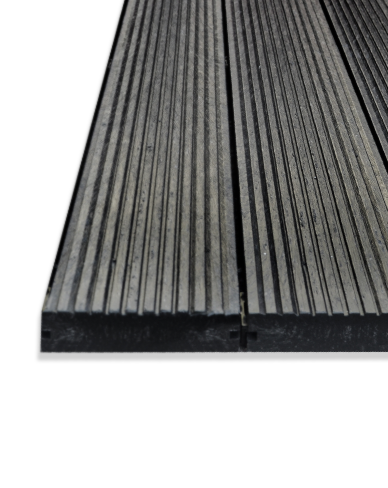

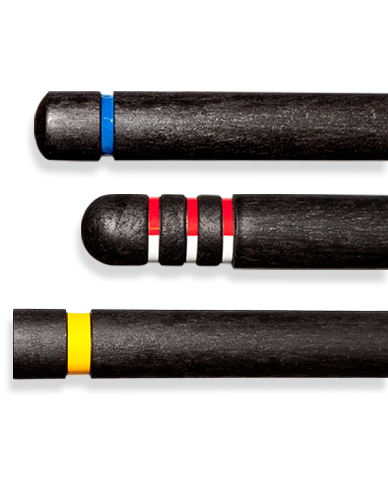

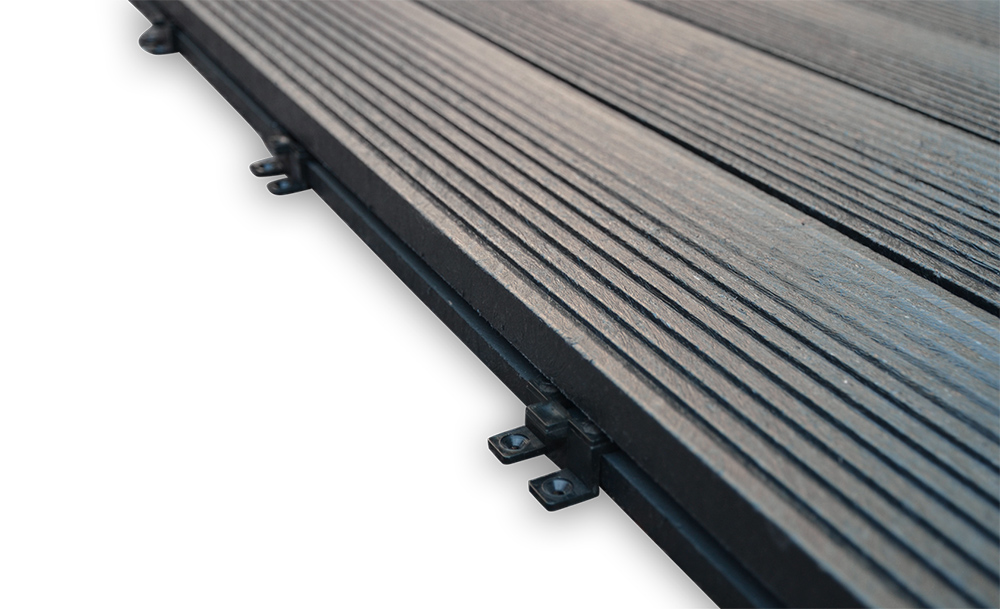

“The material is extremely versatile being suitable for a variety of products such as joists, decking, rails, fences, boardwalks and also outdoor furniture. And when it comes to longevity, plastic timber has several additional benefits. It is fully weather-proof and easy to clean, which makes it more hygienic than traditional timber alternatives,” she says.

It is also resistant to attacks by insects and has less risk of rotting or degrading with age, certainly compared with wood over a comparable time, meaning it remains entirely durable and long-lasting even in the most challenging of environments. Just as importantly, plastic timber is maintenance free and does not require painting or chemical treatment at any point in its life span, saving both time and cost in comparison to the upkeep of more traditional materials.

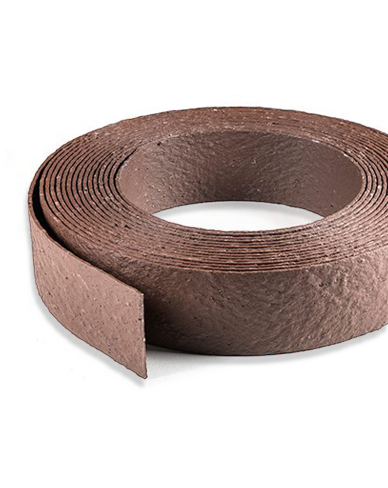

The process of turning plastic waste into useful second life products involves the collected items going through a series of rigorous quality checks as they pass through the remanufacturing process that sees the plastic shredded, washed, blended and melted, ready for extrusion into timber profiles.

Lorek-Wallace adds: “While the recycled plastic profiles are ideal for many requirements, from the landscaper looking for a planter to the builder constructing a revetment wall, all products can also be recycled and remanufactured multiple times over, thus continuing the circular economy journey.”

Part of the solution

“Achieving a comprehensive circular economy is understandably a long-term challenge, but it is something that industries need to aim for in order to ensure we create a world fit for future generations,” she continues.

“In the construction world, the adoption of plastic timber may be a small step but it a significant one, and one that will also find particular favour with consumers, given the current media focus on the problems of plastic waste and pollution. In this way, plastic waste becomes less of a problem and more part of the solution.”

“In demonstrating a practical use for used plastic through plastic timber to replace conventional materials, builders can easily demonstrate a positive sustainability commitment – and just as important they have a functional and reliable product that will deliver many long-term benefits for both them and their customers.”